HOW the biodegradation/COMPOSTING of BIOCOVERS® functions

All our BIOCOVERS® qualities are made of 100% biofibres PLA or biofibres PLA plus natural fibres (wool, hemp…). Given our production process there is no need of binders to turn these fibres into a nonwoven mat.

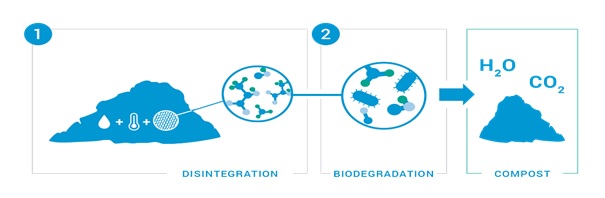

The biodegradation is a 2-step degradation process:

1. DISINTEGRATION: moisture and heat in the compost pile split the polymer chains apart, creating smaller polymers, and finally, lactic acid.

2. BIODEGRADATION: microorganisms in compost and soil consume the smaller polymer fragments and lactic acid as nutrients. Since lactic acid is widely found in nature, a large number of organisms metabolize lactic acid.

The end result of composting is carbon dioxide, water and humus, a soil nutrient. This degradation process is temperature and humidity dependent.

Only higher temperatures in combination with high humidity rates will lead to a quick composting. These conditions are present in industrial composting and specific municipal facilities.

In normal European weather conditions degradation will take a long time and will largely depend on the presence of heat and moisture and microorganism. If one of this 3 elements is not present the degradation will go substantially slower.

European regulations concerning biodegradation and composting: the sole reference is the European standard EN 13432, requirements made for biodegradable packing materials but commonly accepted for other types of bioplastics.

Some BIOCOVERS® qualities are tested and have the OK Compost Industrial label (TÜV AUSTRIA (formerly Vinçotte) - a certification body authorised by European Bioplastics )

These qualities were undergoing 4 different tests:

1/ test on biodegradation (chemical break down of the biopolymer into carbon dioxide, water and biomass)

2/ test on disintegration (physically falling apart of the product in small fragments)

3/ test on ecotoxicity (test if the composted product does not exert any negative effect on plants)

4/ test on heavy metals content

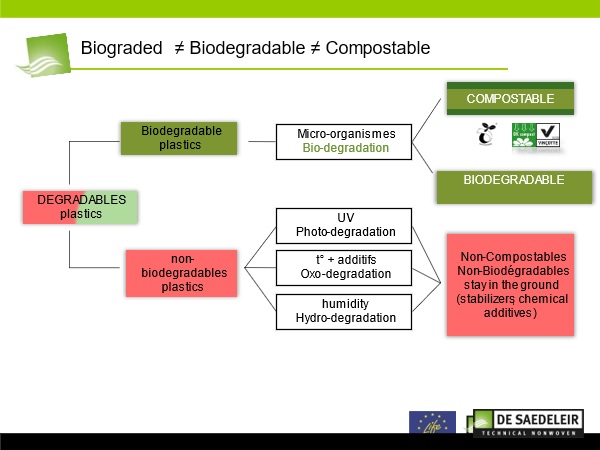

"biodegradable" and "compostable" do not mean the same thing: biodegradable product may be broken down by microorganisms, but this does not necessarily imply that the product will biodegrade into good quality compost. In this way a compostable product can be more useful than a biodegradable product.

Compostability relies heavily on the environment where the product is broken down. As each environment (compost, soil, water, …) has different temperatures and microorganisms, the speed of the biodegradation process may vary from one site to another. Also the density of the different natural materials will lead to completely different life times.

- For example in our garden some vegetal plant or tree material might stay present for 10 or 20 years or more.

- The same vegetal material will compost/biodegrade quickly in in a well kept municipal compost site (temperature > 55-60°C + sufficient humidity) or industrial composting plants. Given the success of bioplastics the development of such facilities is growing internationally.

As our biomats are requested for long term use and not for ‘shorter’ periods like 1 or 2 seasons, they are not developed to get OK compost home (disintegration of 90% of the material within 6 months) or OK biodegradable soil (disintegration of minimum 90% of the material within a period of 24 months).

The qualities with the label OK compost have a label + number.

Difference between degradation / biodegradation / oxodegradation