FAQ

At BIOCOVERS®, we understand that choosing the right sustainable solutions often raises important questions. That’s why we’ve created this FAQ page to provide clear and concise answers to the most common inquiries about our products, services, and mission.

Whether you’re curious about how our biodegradable covers work, need guidance on selecting the right product for your needs, or want to learn more about our commitment to sustainability, you’re in the right place.

Explore the sections below to find the information you need, and don’t hesitate to contact us if you have additional questions or require personalized assistance. We’re here to help!

Why making biomaterials like PLA?

- The raw material for PLA -starch- is available all over the world

- For some applications PLA can be a supplement or an alternative for synthetic or natural fibre products

Why making PLA-biofibres and PLA-textiles?

- PLA-fibres have their own caracteristics (UV-stable, FR, thermomoladble…)

- PLA-fibres can be given an ideal thickness, length, shape so they can be lead to more performant end products (not only biobased & compostable but also lighter, stronger, easy to handle, more homogenous…)

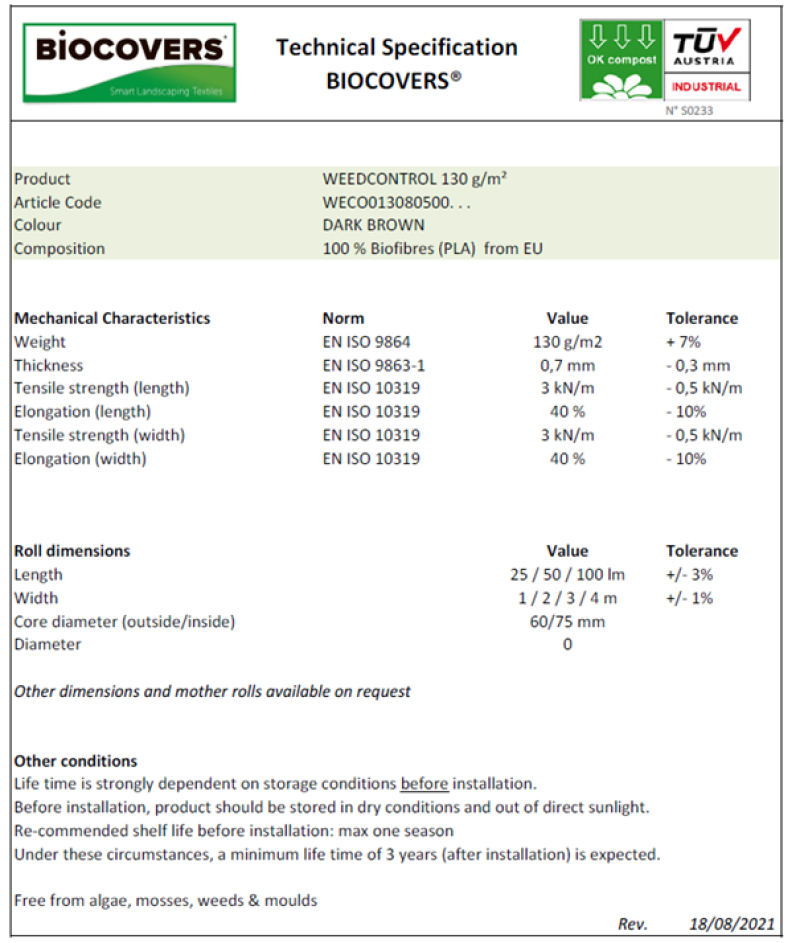

- Continous supply, production in Europe

All our BIOCOVERS® qualities are made of 100% biofibres PLA or biofibres PLA plus natural fibres (wool, hemp…). Given our production process there is no need of binders to turn these fibres into a nonwoven mat.

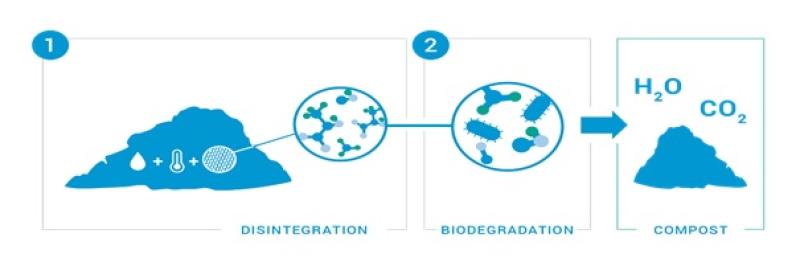

The biodegradation is a 2-step degradation process:

1. DISINTEGRATION: moisture and heat in the compost pile split the polymer chains apart, creating smaller polymers, and finally, lactic acid.

2. BIODEGRADATION: microorganisms in compost and soil consume the smaller polymer fragments and lactic acid as nutrients. Since lactic acid is widely found in nature, a large number of organisms metabolize lactic acid.

The end result of composting is carbon dioxide, water and humus, a soil nutrient. This degradation process is temperature and humidity dependent.

Only higher temperatures in combination with high humidity rates will lead to a quick composting. These conditions are present in industrial composting and specific municipal facilities.

In normal European weather conditions degradation will take a long time and will largely depend on the presence of heat and moisture and microorganism. If one of this 3 elements is not present the degradation will go substantially slower.

European regulations concerning biodegradation and composting: the sole reference is the European standard EN 13432, requirements made for biodegradable packing materials but commonly accepted for other types of bioplastics.

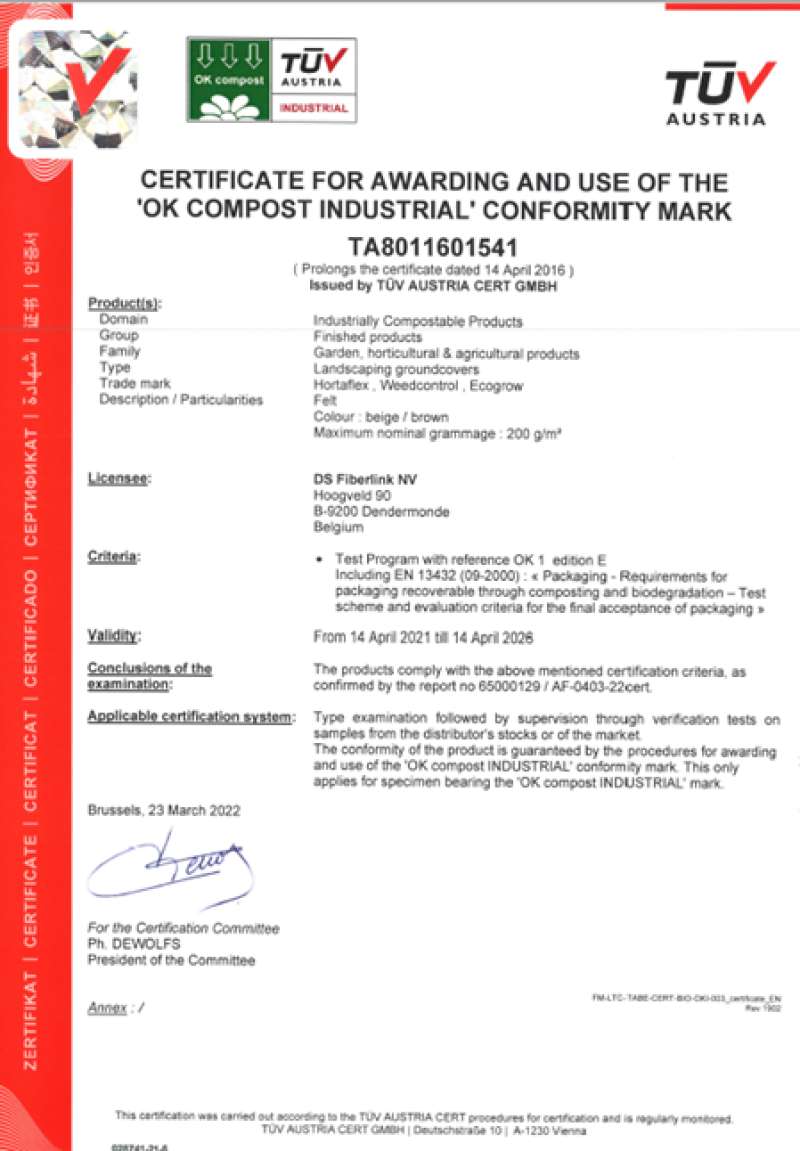

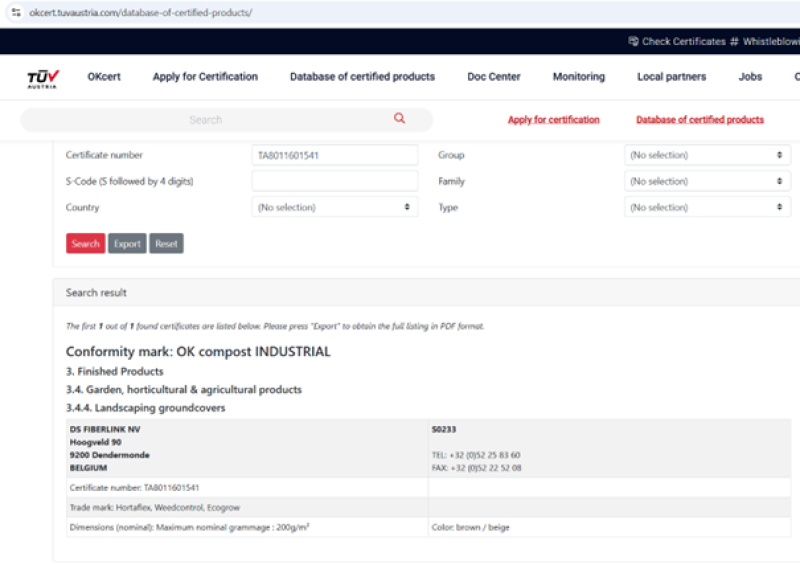

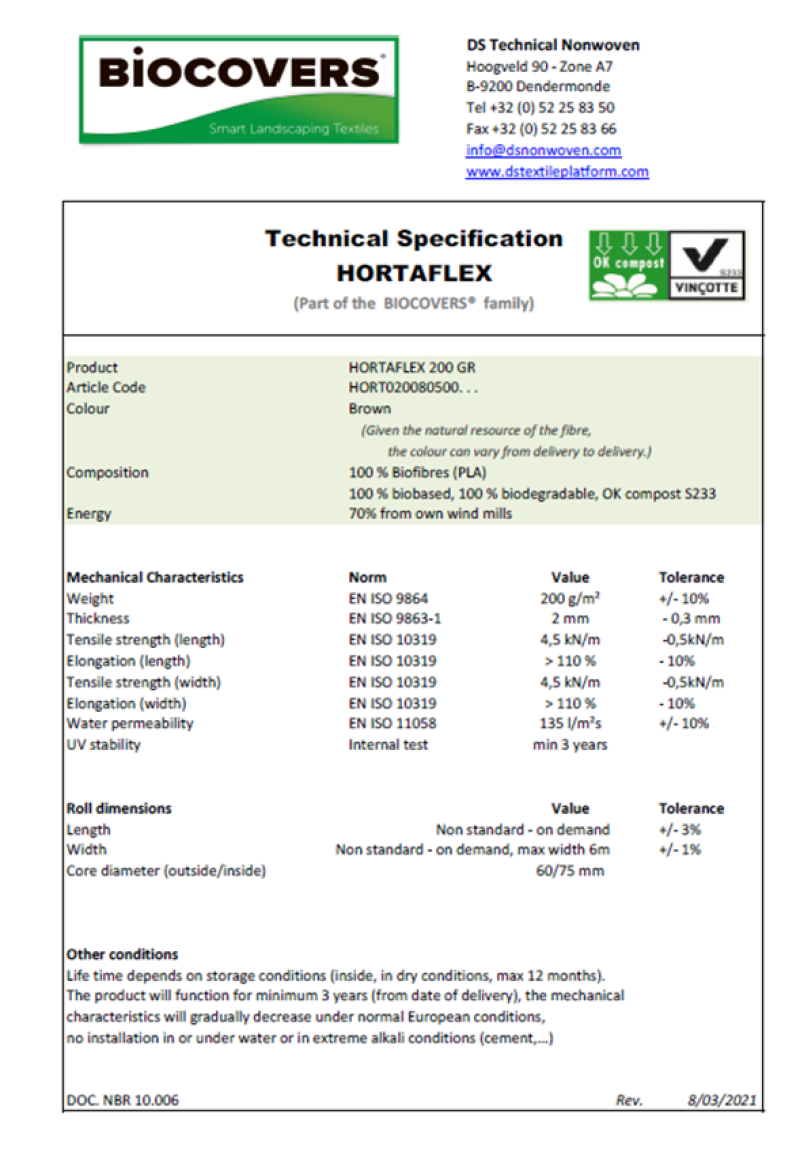

Some BIOCOVERS® qualities are tested and have the OK Compost Industrial label (TÜV AUSTRIA (formerly Vinçotte) - a certification body authorised by European Bioplastics )

These qualities were undergoing 4 different tests:

- test on biodegradation (chemical break down of the biopolymer into carbon dioxide, water and biomass)

- test on disintegration (physically falling apart of the product in small fragments)

- test on ecotoxicity (test if the composted product does not exert any negative effect on plants)

- test on heavy metals content

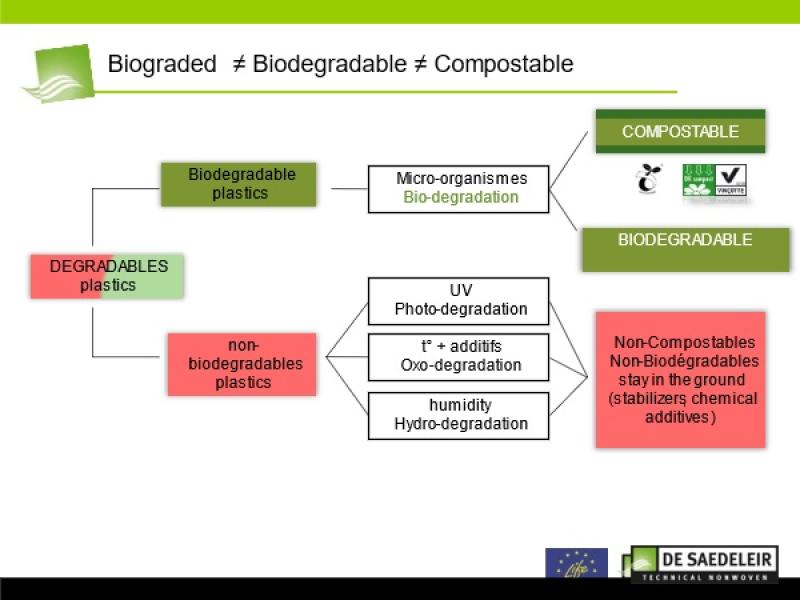

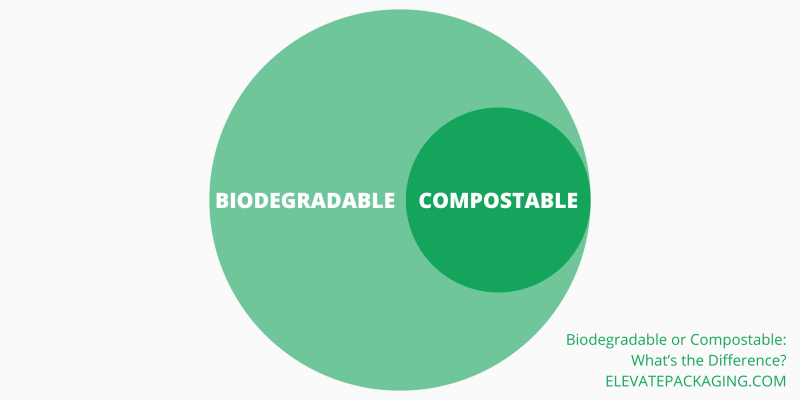

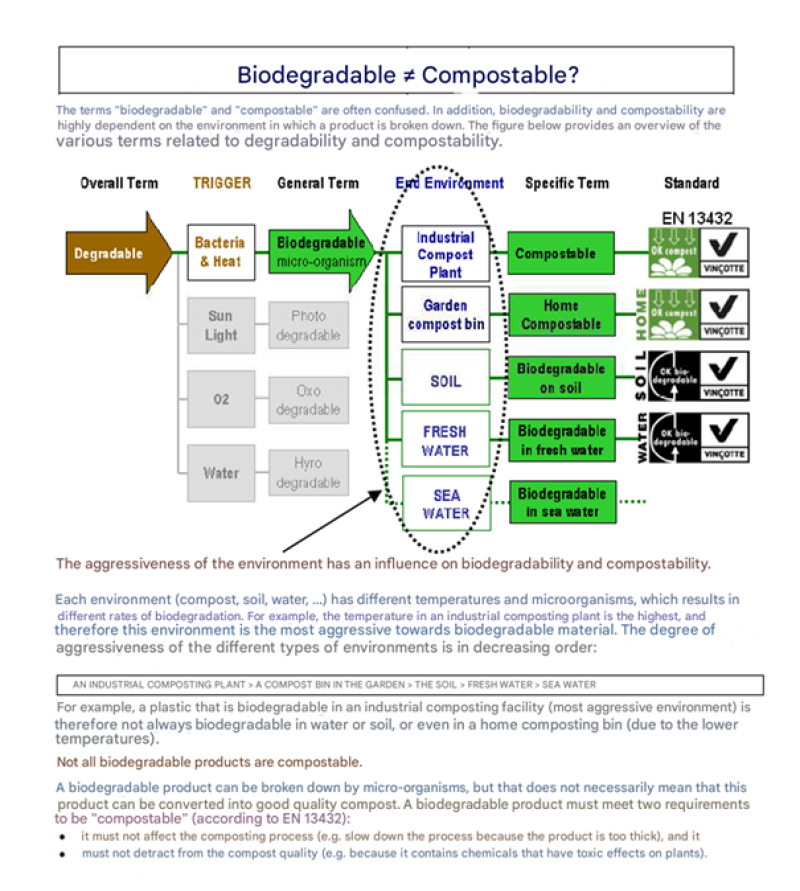

"Biodegradable" and "compostable" do not mean the same thing: biodegradable product may be broken down by microorganisms, but this does not necessarily imply that the product will biodegrade into good quality compost. In this way a compostable product can be more useful than a biodegradable product.

Compostability relies heavily on the environment where the product is broken down. As each environment (compost, soil, water, …) has different temperatures and microorganisms, the speed of the biodegradation process may vary from one site to another. Also the density of the different natural materials will lead to completely different life times.

- For example in our garden some vegetal plant or tree material might stay present for 10 or 20 years or more.

- The same vegetal material will compost/biodegrade quickly in in a well kept municipal compost site (temperature > 55-60°C + sufficient humidity) or industrial composting plants. Given the success of bioplastics the development of such facilities is growing internationally.

As our biomats are requested for long term use and not for ‘shorter’ periods like 1 or 2 seasons, they are not developed to get OK compost home (disintegration of 90% of the material within 6 months) or OK biodegradable soil (disintegration of minimum 90% of the material within a period of 24 months).

The qualities with the label OK compost have a label + number.

Difference between degradation/biodegradation/oxodegradation

All plastics — whether biodegradable or not — will eventually break down during their degradation process. Over time, they form particles smaller than 5 mm, known as microplastics. Not all microplastics are harmful. In fact, microplastics derived from the biobased material PLA can biodegrade or be composted.

Our biobased BIOCOVERS®are designed for specific uses: weed control and geotextile applications, not for short-term or temporary uses such as certain packaging or agricultural films that are plowed under after harvest.

After a certain lifespan, and if left in nature, our PLA-based fabrics will gradually degrade. They will break down into smaller segments which, due to their size, may be classified as microplastics. However, PLA microplastics are not harmful to flora, fauna, or the human body (see below: “Is PLA harmful for the human body?”).

Unlike oil-based nonwovens, PLA-based nonwovens will continue to break down — in the presence of sufficient moisture, temperature, and microorganisms — into naturally occurring elements (water, CO₂, and compost). This process is known as composting.

What is clear and certain:

- Oil-based plastics will eventually break down into microplastics that will never be biodegradable or compostable.

- PLA biobased plastics will also fragment into microplastics, but under suitable composting conditions, they will further biodegrade into water, CO₂, and compost.

- Even if PLA-based plastics degrade slowly due to lack of heat or moisture, these biobased microplastics do not pose a threat to human health or the environment (see below).

Can PLA Microplastics Be Harmful to the Human Body?

For our applications in landscaping, a long-lasting biopolymer like PLA is essential. PLA has a sufficiently long lifespan for climates across Southern, Central, and Northern Europe.

PLA degrades slowly in European conditions, but that doesn’t mean it won’t eventually biodegrade or compost.

We intentionally use a slow-degrading biopolymer like PLA because our products are meant to last. As a result, PLA may fragment into microplastics — but unlike oil-based plastics, these fragments are not, and will not become, harmful to the human body.

Is PLA harmful to the human body?

The answer is clearly: NO.

The same PLA biopolymer used in our Biocovers is also used in highly regulated food and medical applications, such as:

- Tea bags: In Europe, many tea bags are now made from PLA. These bags are steeped in near-boiling water that is then consumed — meaning PLA enters our digestive system. These are approved by EFSA (European Food Safety Authority), known for its strict health and toxicity standards.

- Food packaging: Used for products such as yogurt containers and coffee capsules.

- Medical applications: PLA is used in medical wipes and even implants placed inside the human body.

Other examples where PLA may enter the human system include:

- Food serviceware: Plates, cutlery, paper hot cups, etc.

(NatureWorks - Food Serviceware) - Hygiene products: Face masks, baby wipes, and other sanitary products

(NatureWorks - Medical and Hygiene) - Agricultural applications: Biodegradable mulch films

(European Bioplastics FAQ)

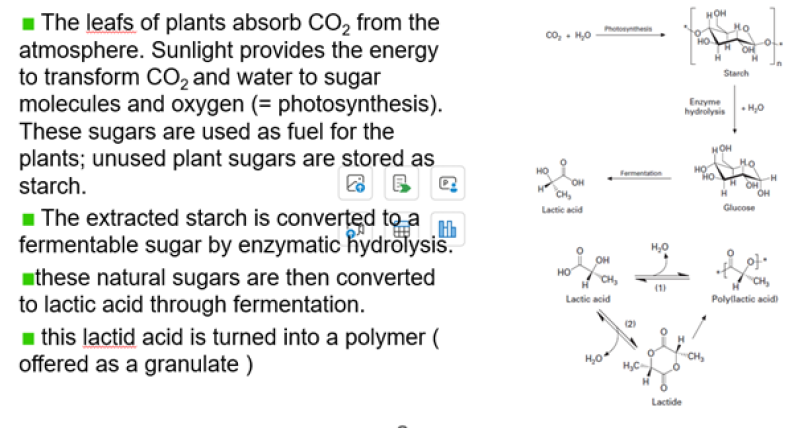

1. PLA is plant based.

Plants need Carbon dioxide (CO2)

- a primary greenhouse gas emitted through human activities – as a raw material, they are build from it.

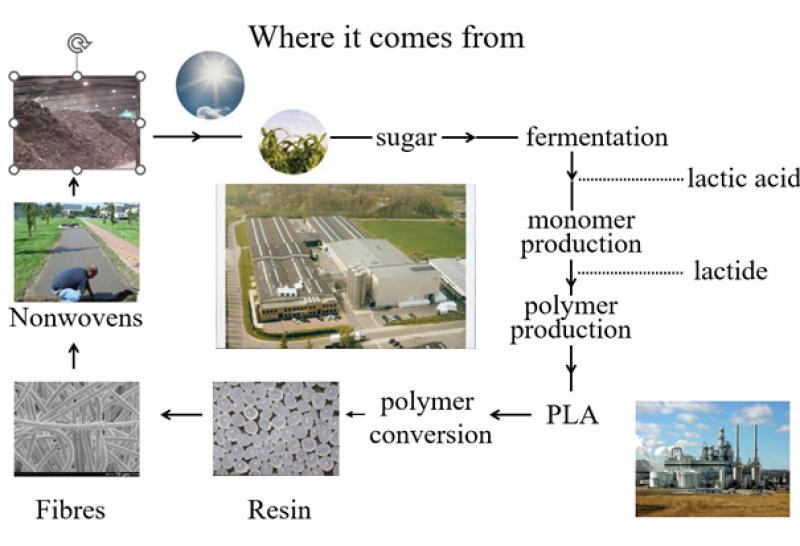

2. Creating Lactic Acid

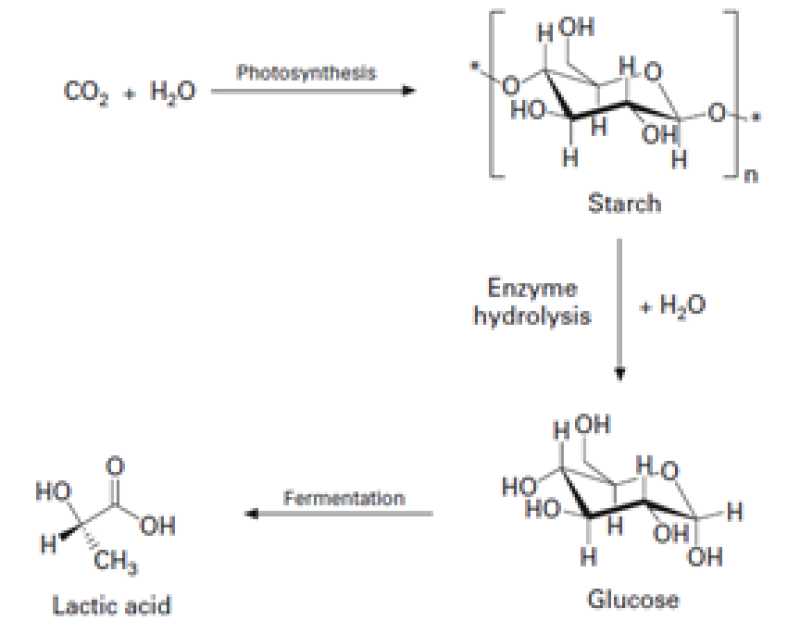

The plants are put through a milling process extracting the starch (glucose). Enzymes are added to convert the glucose to dextrose via a process called hydrolysis. Microorganisms then ferment this dextrose into lactic acid.

3. Transforming Lactic Acid to Lactide

A proprietary two-step process transforms lactic acid molecules into lactide

4. Polymerizing Lactide into PLA

In the process of polymerization, the lactide ring is opened and linked together to form the long chain of polylactide polymer. These PLA granules are used in a wide-range of innovative products including coffee capsules, yogurt cups, baby wipes, agrotextiles, geotextiles...

The chemical process PLA granulate:

Production process Biofibres & biononwoven

- For the production of PLA staple fibres and PLA nonwoven mats only energy, biobased colour additives, steam and water are needed. The main energy is electricity from own windmills.

- Biofibres and biomats can be produced on the same production lines as the ones needed for PP/PET/PA/PE… There is a low transition cost to switch the production from non-biobased to biobased products.

- All our BIOCOVERS® qualities are made of 100% biofibres PLA or biofibres PLA plus natural fibres (wool, hemp…). Given our production process there is no need of binders to turn these fibres into a nonwoven mat.

In quite some cases using biofibres and biomats means a responsible material choice and is mostly a step forward in the direction of a circular economy (cradle to cradle)

All our BIOCOVERS® qualities are made of 100% biofibres PLA or biofibres PLA plus natural fibres (wool, hemp…).

The biofibres PLA are 100% plant based.

Given our production process there is no need of binders to turn these fibres into a stable and strong nonwoven mat. The mechanical characteristics are a result of a right blend of fibres, mechanical and thermical bonding.

The composition of our BIOCOVERS® is clearly mentioned in our technical data sheets and as in the production process no other non-biobased materials are used (they are 100% biobased).

BIOCOVERS® consists of plant based elements only and no oil/mineral based materials.

BIOCOVERS® starts with nature and goes back to nature…

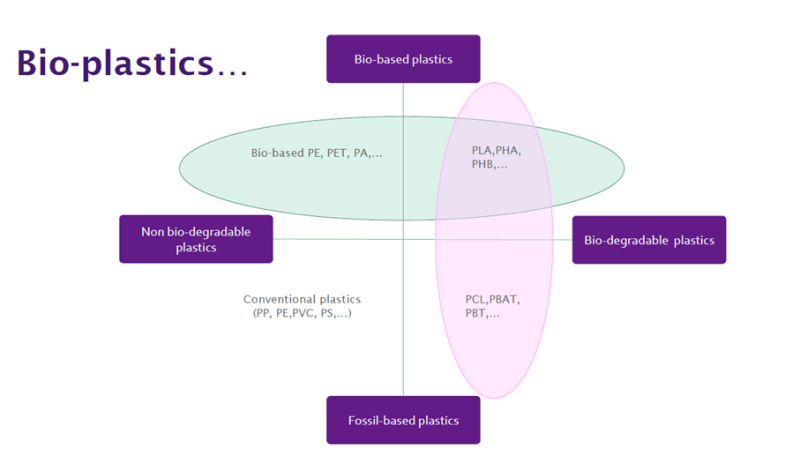

Biobased Polymer

A biobased polymer is produced from renewable raw materials (plant-based), meaning it is derived directly or indirectly from biomass.

- Direct: The biopolymer is made from plants rich in starch or sugar (e.g. sugar beets, sugarcane).

- Indirect: The biopolymer is 100% made from by-products or residual streams of the food industry.

In practice, these residual streams are the most commonly used raw material.

In contrast, conventional polymers are derived from fossil-based raw materials, such as oil.

⚠️ Note: The term “bioplastics” is overly broad and potentially misleading.

We strongly recommend using the term “biobased plastics” instead.

Biodegradable Polymer

A biodegradable polymer is a material that is broken down in the soil by microorganisms.

The speed of this biodegradation depends on temperature, moisture, and soil conditions.

⚠️ Important considerations:

- Under European regulations, no specific time limit is defined — meaning the biodegradation process may take anywhere from a short to a very long time.

- In some cases, residues from the process may inhibit plant growth (e.g. certain residues from the citrus industry).

In other words:

- This is a vague and general term, and does not guarantee that the material is 100% biobased.

- In Anglo-Saxon countries, this term is often misused — for example, by claiming that PET is biodegradable. While PET may fragment, its micro-fragments will never fully biodegrade (or only to a very small extent).

Compostable Polymer

A compostable product is also broken down in the soil by microorganisms, but in this case, the end products include CO₂, water, and humus (compost) — a useful material for soil and plant growth.

Additional key aspects:

- The process must ensure no harmful substances remain. During plastic extrusion, additives such as stabilizers and colorants are often used — some of which may be harmful to flora and fauna. This is especially relevant in discussions about microplastics, plastic pollution in oceans, contaminated fish, and the declining fertility of marine species.

- The composted product must not negatively impact plant growth.

- According to European legislation, the speed of composting is a crucial factor.

Therefore, composting goes a step further than biodegradation and implies stricter and more useful outcomes.

To determine whether a biopolymer is compostable, four tests are required under the European composting standard EN 13432:

- Biodegradation test (chemical breakdown into CO₂, water, and biomass)

- Disintegration test (physical breakdown into small fragments)

- Ecotoxicity test (ensures no negative effect on plant growth)

- Heavy metal content test

Depending on the composting conditions and speed, products may receive certification such as:

- OK compost INDUSTRIAL:

Requires 90% of the material to degrade within 6 months at 55–60°C and high humidity (>90% RH) - OK compost HOME (soil):

Requires 90% degradation within 6 months at 25–30°C

Regulatory limitations:

There is no existing “OK compost SOIL” certification that tests whether a biopolymer degrades over a period of 3 to 5 years or more.

Such long-term testing would be highly relevant for our applications (e.g. landscaping), but it is not currently feasible — mainly due to cost and complexity.

All compostable products are biodegradable,

but not all biodegradable products are compostable.

PS:

If insufficient oxygen is present during degradation (e.g. in old or sealed landfill sites), the process may result in the formation of methane.

Methane is a potent greenhouse gas, trapping 23 times more heat than the same amount of CO₂.

Lifespan of Biocovers

How long does degradation and composting take?

(see also the section on composting)

- If the bio-nonwoven is stored in dry and cool conditions and does not come into contact with microorganisms, it will not biodegrade.

- When used in Europe, the biological degradation process will take a long time (>5 years), but not centuries as with conventional oil-based plastics such as PP, PET, PE, or PA.

- When used outdoors in tropical regions, where high humidity and elevated temperatures combine, biological degradation may occur within a few years or even faster.

- If composted at an industrial composting facility, the biological degradation/composting will occur within 6 months (90%).

Too long??

People often ask what the “right” lifespan of our biocovers is.

It turns out to be longer than initially expected — which, in landscaping and geotextile applications, is often more of an advantage than a disadvantage!

Sometimes it’s said that the fabric hasn’t composted after 5 or even 10 years — which to some, seems too long...

But let’s consider what we see in nature and rarely talk about:

In Europe, many types of wood used underground have a lifespan of 15 to 25 years, and when used above ground, they last even longer.

For example, a piece of oak lying in a garden can remain visibly intact for more than 20 years. These and many other European wood species only rot or compost after many years — sometimes after 20 years or more.

So, a long lifespan should not be taken as proof that a product cannot compost, nor should it cast doubt on its 100% plant-based origin.

According to the definitions in European regulation, we will never obtain an OK compost SOIL certificate — and that’s actually a good thing, since it would mean our product would compost within 12 months, which would be far too short for our intended use.

Many European wood types also take a long time to compost – see for example durability class 2:

The European standard EN 350-2 defines durability classes for most wood species used in Europe.

Each wood species is classified based on the natural durability of its heartwood (the central, dense part of the trunk), in terms of its resistance to rot and fungi.

The classification is based on a test where a 50x50 mm stake is placed into the ground. The longer the average lifespan of the wood, the higher the durability.

When used above ground, these wood types typically last about 10 years longer.

Testing is only done with heartwood, since sapwood is never considered durable and always falls into durability class V.

Wood Durability Class II:

- Lifespan between 15 and 25 years

- Examples: European Oak, Robinia (Black Locust), Chestnut, Western Red Cedar, and modified pine or spruce

Granulate

- For the production of PLA granulate no other raw material than natural vegetal material and energy is needed

- The underlaying idea of biogranulate is ‘It comes from nature and it goes back to nature‘ :

- Leafs of plants absorb CO2 from the atmosphere. Sunlight provides the energy to transform CO2 and water to sugar molecules and oxygen (= photosynthesis).

These sugars are used as fuel for the plants; unused plant sugars are stored as starch. - The extracted starch is converted to a fermentable sugar by enzymatic hydrolysis.

- These natural sugars are then converted to lactic acid through fermentation.

- This lactid acid is turned into a polymer (offered as a granulate)

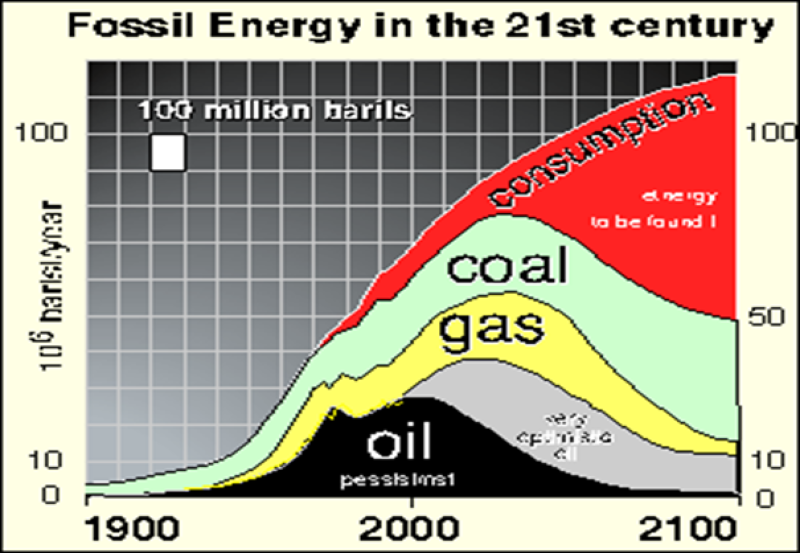

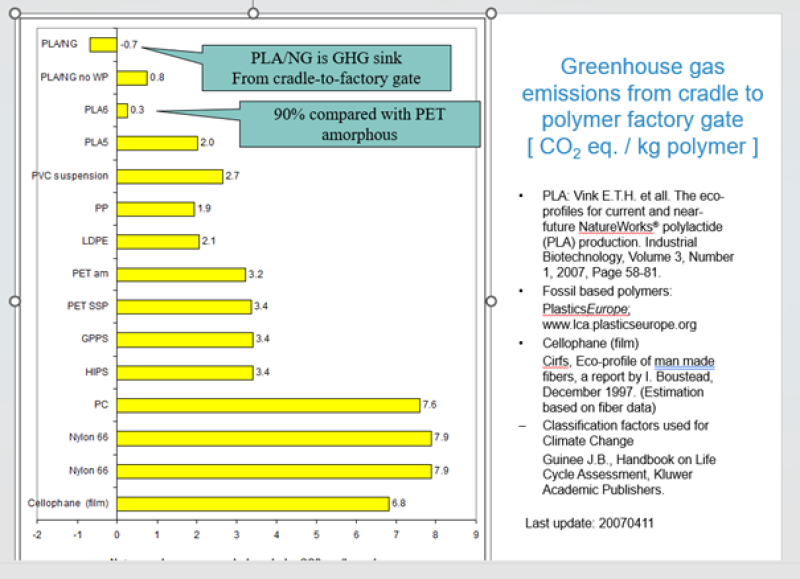

- The energy needed to make PLA-granulate is substantially lower than the one needed for classic oil based polymers like PET/PP/PA/PE …

Also see : https://www.natureworksllc.com/What-is-Ingeo/How-Ingeo-is-Made

Biofibres & biononwoven

- For the production of PLA staple fibres and PLA nonwoven mats only energy, biobased colour additives, steam and water are needed. The main energy is electricity from own windmills.

- Biofibres and biomats can be produced on the same production lines as the ones needed for PP/PET/PA/PE… There is a low transition cost to switch the production from non-biobased to biobased products.

- In quite some cases using biofibres and biomats means a responsible material choice and is mostly a step forward in the direction of a circular economy (cradle to cradle)

1/ OK Compost label

Former: Vinçotte, now TUV (same European regulations)

2/ Seedling Label

The Seedling label is a label designed by European Bioplastics to mark products across Europe that comply with EN 13432 / 14995 (this is the standard on which Vincotte bases its OK Compost certification).

The labels used by different institutes (such as OK Compost or Seedling) are sometimes only used locally...

3/Certification DS : OK Compost Industrial ( for all the 100% PLA qualities)

Send us your questions

Don’t hesitate to contact us if you have additional questions or require personalized assistance