What is the production process for biogranulate PLA?

Granulate

- For the production of PLA granulate no other raw material than natural vegetal material and energy is needed

- The underlaying idea of biogranulate is ‘It comes from nature and it goes back to nature‘ :

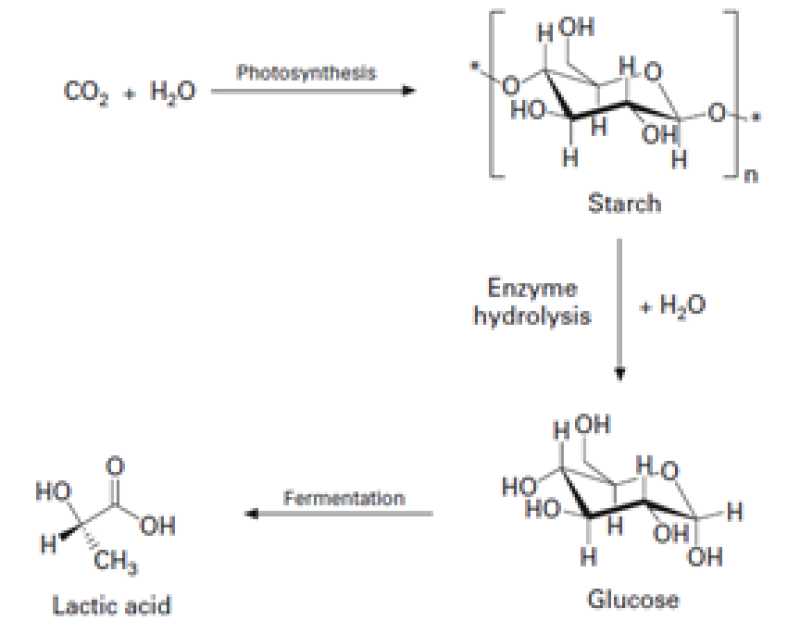

- Leafs of plants absorb CO2 from the atmosphere. Sunlight provides the energy to transform CO2 and water to sugar molecules and oxygen (= photosynthesis).

These sugars are used as fuel for the plants; unused plant sugars are stored as starch. - The extracted starch is converted to a fermentable sugar by enzymatic hydrolysis.

- These natural sugars are then converted to lactic acid through fermentation.

- This lactid acid is turned into a polymer (offered as a granulate)

- The energy needed to make PLA-granulate is substantially lower than the one needed for classic oil based polymers like PET/PP/PA/PE …

Also see : https://www.natureworksllc.com/What-is-Ingeo/How-Ingeo-is-Made

Biofibres & biononwoven

- For the production of PLA staple fibres and PLA nonwoven mats only energy, biobased colour additives, steam and water are needed. The main energy is electricity from own windmills.

- Biofibres and biomats can be produced on the same production lines as the ones needed for PP/PET/PA/PE… There is a low transition cost to switch the production from non-biobased to biobased products.

- In quite some cases using biofibres and biomats means a responsible material choice and is mostly a step forward in the direction of a circular economy (cradle to cradle)