What does biodegradable mean?

Biobased Polymer

A biobased polymer is produced from renewable raw materials (plant-based), meaning it is derived directly or indirectly from biomass.

- Direct: The biopolymer is made from plants rich in starch or sugar (e.g. sugar beets, sugarcane).

- Indirect: The biopolymer is 100% made from by-products or residual streams of the food industry.

In practice, these residual streams are the most commonly used raw material.

In contrast, conventional polymers are derived from fossil-based raw materials, such as oil.

⚠️ Note: The term “bioplastics” is overly broad and potentially misleading.

We strongly recommend using the term “biobased plastics” instead.

Biodegradable Polymer

A biodegradable polymer is a material that is broken down in the soil by microorganisms.

The speed of this biodegradation depends on temperature, moisture, and soil conditions.

⚠️ Important considerations:

- Under European regulations, no specific time limit is defined — meaning the biodegradation process may take anywhere from a short to a very long time.

- In some cases, residues from the process may inhibit plant growth (e.g. certain residues from the citrus industry).

In other words:

- This is a vague and general term, and does not guarantee that the material is 100% biobased.

- In Anglo-Saxon countries, this term is often misused — for example, by claiming that PET is biodegradable. While PET may fragment, its micro-fragments will never fully biodegrade (or only to a very small extent).

Compostable Polymer

A compostable product is also broken down in the soil by microorganisms, but in this case, the end products include CO₂, water, and humus (compost) — a useful material for soil and plant growth.

Additional key aspects:

- The process must ensure no harmful substances remain. During plastic extrusion, additives such as stabilizers and colorants are often used — some of which may be harmful to flora and fauna. This is especially relevant in discussions about microplastics, plastic pollution in oceans, contaminated fish, and the declining fertility of marine species.

- The composted product must not negatively impact plant growth.

- According to European legislation, the speed of composting is a crucial factor.

Therefore, composting goes a step further than biodegradation and implies stricter and more useful outcomes.

To determine whether a biopolymer is compostable, four tests are required under the European composting standard EN 13432:

- Biodegradation test (chemical breakdown into CO₂, water, and biomass)

- Disintegration test (physical breakdown into small fragments)

- Ecotoxicity test (ensures no negative effect on plant growth)

- Heavy metal content test

Depending on the composting conditions and speed, products may receive certification such as:

- OK compost INDUSTRIAL:

Requires 90% of the material to degrade within 6 months at 55–60°C and high humidity (>90% RH) - OK compost HOME (soil):

Requires 90% degradation within 6 months at 25–30°C

Regulatory limitations:

There is no existing “OK compost SOIL” certification that tests whether a biopolymer degrades over a period of 3 to 5 years or more.

Such long-term testing would be highly relevant for our applications (e.g. landscaping), but it is not currently feasible — mainly due to cost and complexity.

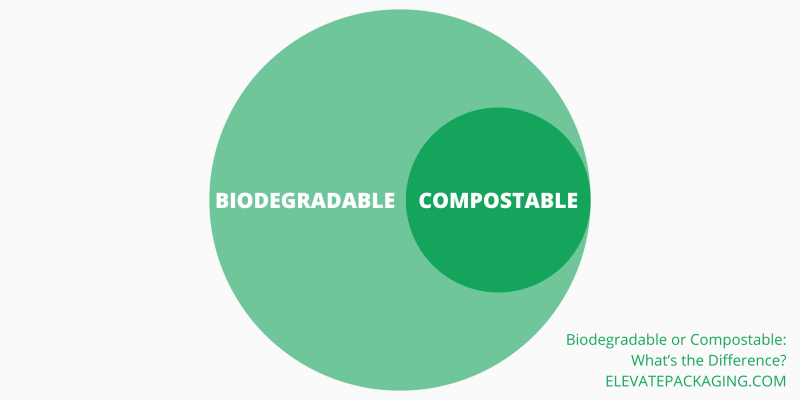

All compostable products are biodegradable,

but not all biodegradable products are compostable.

PS:

If insufficient oxygen is present during degradation (e.g. in old or sealed landfill sites), the process may result in the formation of methane.

Methane is a potent greenhouse gas, trapping 23 times more heat than the same amount of CO₂.