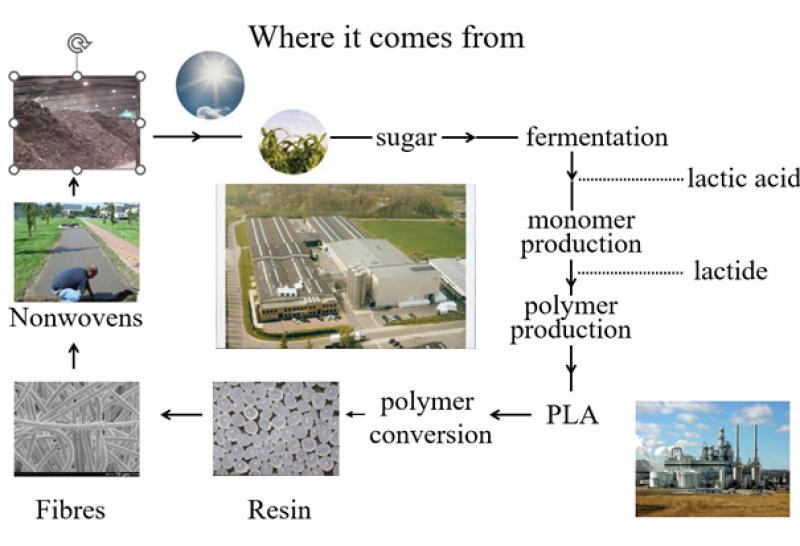

Production process biopolymer PLA (granulate)

1. PLA is plant based.

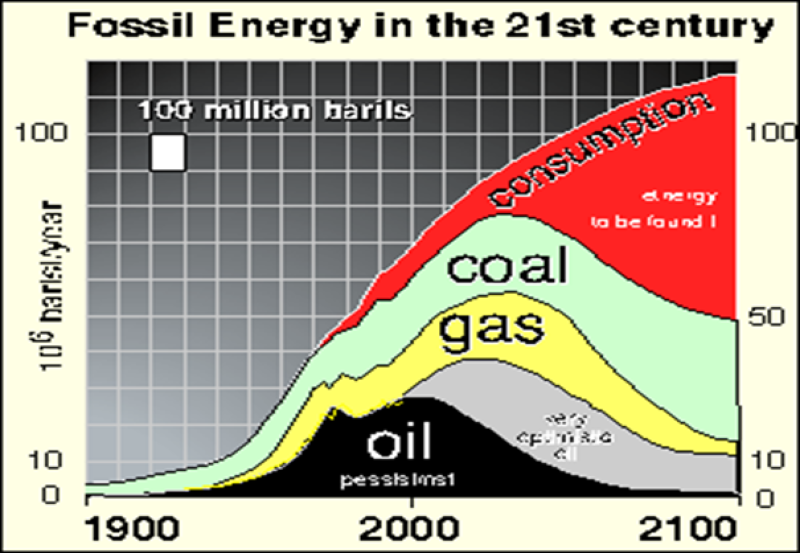

Plants need Carbon dioxide (CO2)

- a primary greenhouse gas emitted through human activities – as a raw material, they are build from it.

2. Creating Lactic Acid

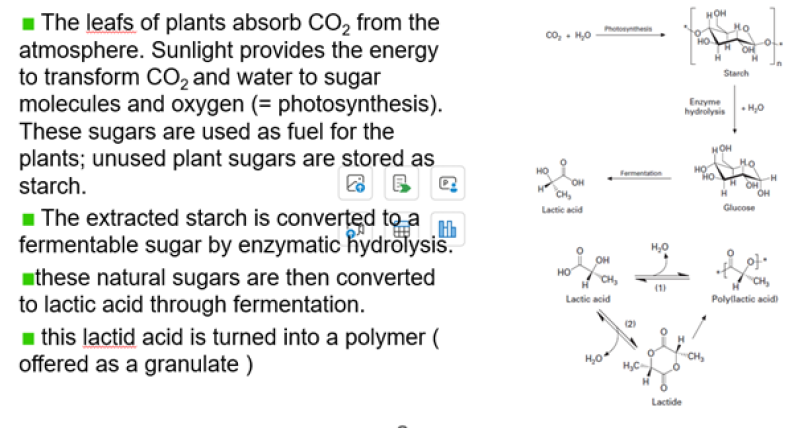

The plants are put through a milling process extracting the starch (glucose). Enzymes are added to convert the glucose to dextrose via a process called hydrolysis. Microorganisms then ferment this dextrose into lactic acid.

3. Transforming Lactic Acid to Lactide

A proprietary two-step process transforms lactic acid molecules into lactide

4. Polymerizing Lactide into PLA

In the process of polymerization, the lactide ring is opened and linked together to form the long chain of polylactide polymer. These PLA granules are used in a wide-range of innovative products including coffee capsules, yogurt cups, baby wipes, agrotextiles, geotextiles...

The chemical process PLA granulate:

Production process Biofibres & biononwoven

- For the production of PLA staple fibres and PLA nonwoven mats only energy, biobased colour additives, steam and water are needed. The main energy is electricity from own windmills.

- Biofibres and biomats can be produced on the same production lines as the ones needed for PP/PET/PA/PE… There is a low transition cost to switch the production from non-biobased to biobased products.

- All our BIOCOVERS® qualities are made of 100% biofibres PLA or biofibres PLA plus natural fibres (wool, hemp…). Given our production process there is no need of binders to turn these fibres into a nonwoven mat.

In quite some cases using biofibres and biomats means a responsible material choice and is mostly a step forward in the direction of a circular economy (cradle to cradle)